Dynamic Dump Design

To access this task:

-

Activate the Design ribbon and select Dump Modelling >> Auto Design. The Auto Dump Design tab is shown by default.

The Dynamic Dump Design Task

This panel is one of Studio OP's automated design tasks. It is similar to the Auto Pit Design task, but applies only to dump designs.

Dynamic Dump Design lets you accurately model alternative dumps and stockpiles in minutes. Designs are automatically merged into complex topographies, may include fixed or adaptive haul roads and can even take account of slope regions to control berm widths and slope angles. Each Lift can be separately constrained and is automatically evaluated to help you compare scenarios. Selected designs can be used by Studio OP’s short and medium-term scheduling.

Note: This function is only available if dump lifts and default dump region slope settings have been defined. You can find out more about prerequisites for this task here.

This is the main console for generating dump data from your constraint strings, slope regions, bench definitions and road definitions. This is where you set up the key parameters for your dump design including selection of constraint strings, interactive road editing (both adaptive and fixed types).

Once the Auto Dump Design panel is active, you can also define automated design template sets.

Tip: Constraining Surfaces, Adaptive Roads and Fixed Roads command groups can be expanded and collapsed.

See Auto Design - Designing Adaptive and Fixed Roads.

Tip: Change the colour of your toe, crest and ramp strings (and other items) using the Advanced Settings panel.

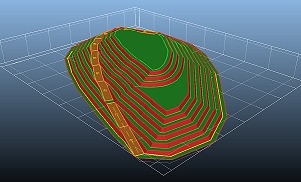

Dump Design Task Outputs

The Auto Dump Design task produces two key outputs:

-

An output wireframe volume file pair representing the closed volume of the dump. This has embedded information describing each lift, using LIFTNUM and LIFTNAME attributes, which can be useful for subdividing the dump volume when short-term scheduling.

-

An evaluation of the volume created by the intersection of the generated dump shell and the specified topography (if no topography is defined, the volume will be generated by closing the lowest toe string of the lowest lift instead).

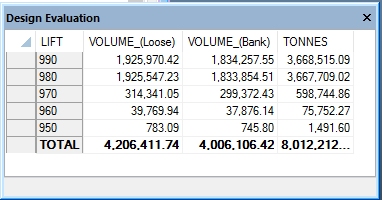

The output report provide a volume report per lift elevation. The evaluation will be performed against the closed volume that results from the intersection with the calculated design surface and the topography assigned to the dump.

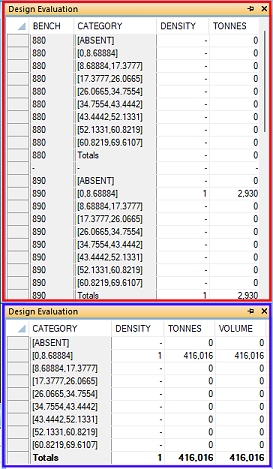

Each lift is reported independently and a grand total is also provided, e.g.:

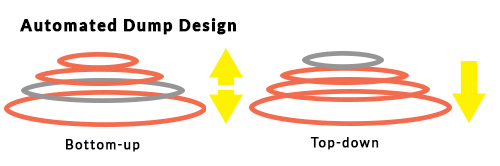

Choosing a Design Direction

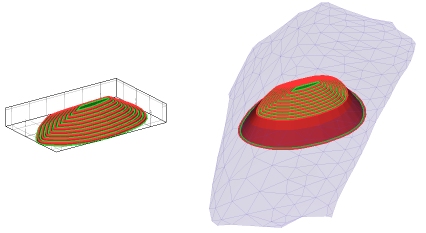

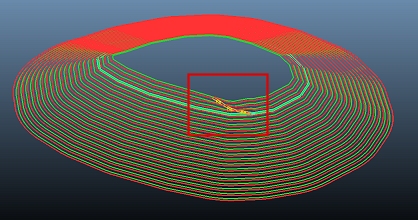

Where a topography is specified for your dump, regardless of the design direction, the toe elevation of the lowest lift will always be positioned at the lowest elevation (Z) value of the topography data. This is done by projecting downwards from the defined crest of the lowest dump lift (as specified using the Dump Design task). Only the first lift is automatically adjusted in this way e.g.:

For example, the image below represents two design outcomes for the same

dump lift definitions; both outcomes are generated using a starting crest

elevation for the first lift of 1000m and 10 successive lifts of 10 meters

thereafter. The image on the left is generated without

a topography definition and the image on the right is the outcome where

a topography has been specified for the dump. In this case, the toe position

of the lowest lift is automatically calculated as the lowest Z value of

the topography, which happens to 890m (topography displayed for clarity):

This has implications for adaptive road design; where a bottom-up design is created (projecting upwards from the constraint string to the upper lift definition, but also downwards to the lowest toe string of the lowest lift within the definition) the direction of roads needs to be considered carefully.

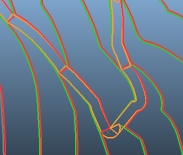

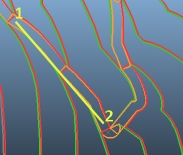

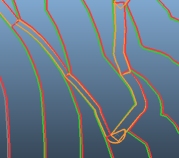

Due the nature of the projection routine, a road cannot cross a constraint string in a dump design. This restriction can be managed using multiple roads, however. For example, in the bottom-up design below, an adaptive road is placed from the constraint string (at 270m elevation) to the top of the dump (at 300m). It is not possible to place a road below the constraint string in this configuration:

To project a road to the lowest lift, you need to

first change the design to a top-down

method and add the second road, selecting a point on the constraint from

which to adapt a road downwards over the lifts, e.g.:

You can then change the design back to a bottom-up project and recalculate the design strings, e.g.:

For more information on how projection is performed for each design direction, see Define Dumps.

Activities

Configure Dump Design General Settings

To configure general auto dump design settings:

-

Select the Dump for which you wish to either create or modify design data. This list includes all dumps previously defined using the Define Dumps task.

-

Choose a Design Direction.

-

To design your dump from the uppermost bench downwards, choose the Top-Down option. Top down designs will ensure the uppermost constraint string represents the top of your dump (lifts defined at elevations above this string will be ignored.

-

To design your dump upwards from the base, choose the Bottom-Up approach. Bottom up designs will project upwards from the lowest constraint string.

See "Choosing a Design Direction", above.

-

Configure Adaptive Roads

Adaptive roads confirm to the contours of your pit or dump design strings and are ultimately used to modify the pit wireframe surface to embed the road in a realistic manner.

- If not already expanded, expand the Adaptive Roads command group.

-

To edit a previously-created road, expand the Name list and pick a road. All road names for the current scenario are listed. You can also select a road by clicking the pointer button and selecting a road string already displayed in the Pit Design 3D window (then click Done).

Alternatively, click New and enter a new Name to add a new road to the selected phase.

Note: Delete an existing road by selecting it and clicking Delete.

-

By default, the road is enabled as Use is checked. You can uncheck this box to remove the road from the design (and re-enable it later if needed).

-

If defining a new road, choose if the adaptive road will initially move up or down the pit or dump in a Clockwise or Counterclockwise direction (imagine a view directly above the pit shell, looking down.

Warning: This direction can't be edited for an existing road. To change the direction of an existing road, it is necessary to delete the original road and recreate it using the other direction option. These options are not available for existing roads.

- Choose the maximum possible Gradient for the road, in either degrees, as a ratio or a percentage value.

-

Choose the berm Width required for the road. Initially you must set a constant width for the road. Once the road has been Recalculated at least once, you can adjust the width of the road along its length from start To the end point. The To field is only enabled for existing roads.

Optionally, for an existing road, click Edit and define a 2-point distance along the section of road you wish to edit. On selecting the second point, the road width will be adjusted accordingly, honouring other design parameters.

In the example below, the road width below the switch is altered from 10m to 5m:

Original road

Set width = 5m

Apply

Tip: If you intend to use a variable road width for a new road, enter the Width first, then Recalculate, then enter the To value and Recalculate again.

-

Configure the Entry Distance. The road entry taper is an important aspect of adaptive road design and the specified distance governs at which point along the starting berm the taper begins.

A larger value will (if it is possible to fit it in) create a more gradual transition from the 'raw' pit profile and the road entry, whilst a zero value, for example, will mean that a constraint string for the starting elevation will be used explicitly to shape the road entry (which isn't initially useful but can be modified to craft a custom entry shape - see below).

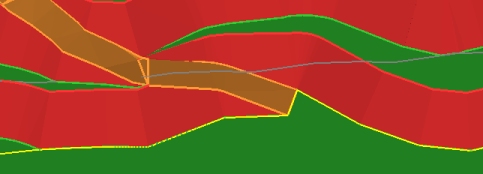

For example, in the image below, the values of zero (0), 20m and 40m are used for the same bottom-up adaptive road. The constraint string at the road start elevation is highlighted in yellow:

Whilst the 0m open pit example is impractical as it stands, the constraint string can subsequently be used to craft the road entry to any custom shape. For example, by manipulating the corresponding pit constraint string of the first example, more controlled road entry can be achieved e.g.:

- Bench

transitions determines how road segments

align, and how this alignment affects the pit or dump around them when

they transition between benches. The Offset

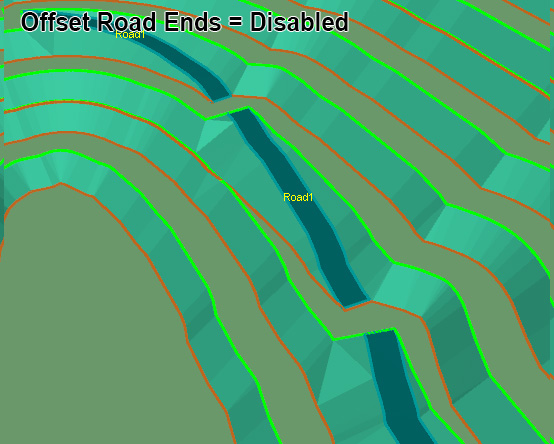

road ends check box can be set independently for each road:

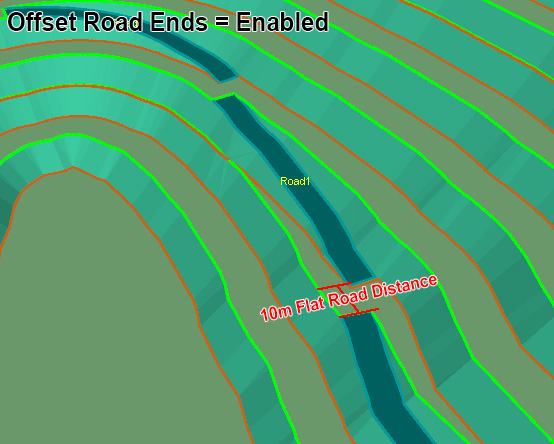

- If Offset road ends is checked, designs start the berm from the inside of the road on a bottom-up design, or the outside on a top down design. This means that the next road segment is offset by the taper width, which can be useful for providing access to berms or lifts. However, it can potentially cause discontinuities in the road that are unwanted.

If Offset road ends is unchecked, road segments are aligned (i.e. not offset).

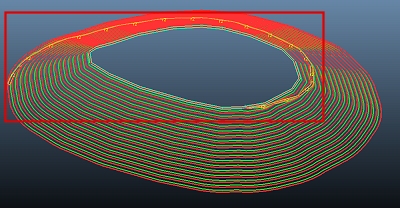

Here's an example of offset vs. non-offset road segments for the same taper width (a 10m flat road distance has been applied as this provides access to the berms or lifts in the offset case:

Note: Whichever way you manage road segment ends, you can choose if and how the pit or dump is modified to accommodate the settings. For example, by disabling the Offset road ends check box, this may mean a road segment has to be oriented differently, meaning the surrounding berm/lift or face should be modified to provide a more natural result. In order to allow the roads to align, the faces on the side of the road may be shallower than specified by the slope regions (they will never be steeper than the current slope region definition allows).

-

You can also choose to perform automated Kink Correction when calculating design strings (and the resulting surface and volume). This setting lets you choose if and how the pit is modified to accommodate road changes.

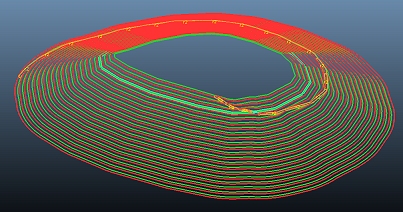

Because each crest string is generated from the previous road profile and berm, the step between the road end and the berm can cause a discontinuity (kink) in the next crest string, for example:

A "kink" may also show up with offset roads which use asymmetrical berm widths and/or different road widths.

If kink correction is checked, you can choose how the correction is applied:

-

None - don't adjust the berm or face to provide a smooth transition between benches. In this example the inside berm or lift width is 1.5, outside width is 5, and road width is 10:

-

By berm - extra width is added to the inside or outside berm to get the outside berm or lift to align with the road end and avoid the discontinuity, and therefore avoid the kink, for example:

-

By face - the next face angle alongside the road is made shallower to push the crest string out and correct the kink, e.g.:

Tip: You can also reduce the impact of bench transitions using global settings such as those found on the Conditioning tab, such as filleting. The settings outlined here are road-specific.

Note: Changing values in the Bench Transitions control group triggers an automatic recalculation of design strings.

-

-

You can add a Switchback to an existing road (if creating a new road, click Recalculate to apply current settings and generate a road item, then you can access the rest of the panel).

Road switchbacks are controlled by the following settings, which apply to all switchbacks on the selected road:

-

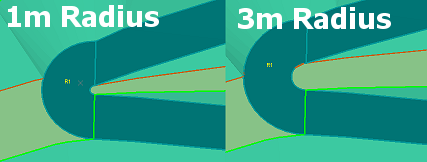

Radius: define the turning radius of the switchback. Increasing the radius will give rise to a switchback covering a larger area. The default value is zero, meaning there will be no internal turning radius, but the outer radius will sweep around whilst maintaining the expected road width and other constraints:

-

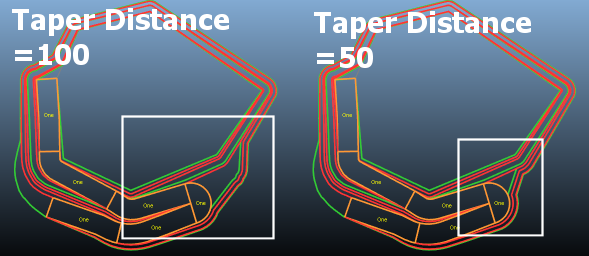

Taper Distance: the taper distance for switchbacks is controlled independently of roads. Use this setting to apply a taper distance to the next switchback (or to an existing one by clicking New Switchback and clicking in the same place as the switchback you wish to modify).

-

Add Switchback: as with the Ramp Layout task, you can add a switchback at any point on the current road segment. Gradient and final elevation settings will continue to be honored where possible. You can also remove any previously-applied switchback from the current road segment.

-

Remove Switchback: remove an existing switchback. Left- or right-click close to the area of a switchback (tip: if multiple switchbacks exist in the same area - zoom in first). Design strings are recalculated automatically on removal of a switchback.

-

-

For a new road, you need to set a start position. Once a road exists, you can reposition its start point and end elevation. How Road Endpoints are modified is affected by your choice of bottom-up or top-down design.

-

For new and existing roads, interactively pick the start position by clicking Choose Start Point and left- or right-clicking a position in the Pit Design 3D view.

Tip: To align your road with a particular design string, Recalculate your design strings and use the filters at the bottom of the screen to show only Design Strings. This can make it clearer to right-click (snap) to a design string on a target level.

-

Once a road exists, its Lower Elevation and Upper Elevation values appear. You can edit these values to fix the start and end points at the desired elevation, either by manually entering a numeric value, or by selecting a bench reference level from each drop-down list. You can also pick a location in the 3D view either by left-clicking (which takes the elevation of the currently active 3D section) or right-clicking to existing data.

Note: The Lower Elevation cannot be above the Upper Elevation.

-

-

Once all adaptive road settings are in place, click Recalculate to create new design strings with updated road properties for your pit or dump design.

-

Save your project.

Configure Fixed Roads

Fixed roads are formed by honouring the specified gradient and start point. The direction is specified interactively.

Initially, a string is drawn to the screen which you should review and edit before you Recalculate your new design strings. Fixed roads are simple to add and remove, and there is a suite of commonly-used string editing commands that will help you construct the most practical access road.

In fact, any string editing command in Studio can be used to modify a fixed road string. Providing the result is possible to use (i.e. a pit can be sensibly constructed to honour start, gradient and other constraints), the resulting design strings will accommodate the fixed road, including all benches above/below the design item (depending on the direction of your design).

Fixed roads will be positioned either through the addition of material (embankment) or excavation (box cut). All pit constraints will be honoured. See Road Design Tips for more information on the most effective use of these commands.

To configure a fixed road:

-

If not already expanded, expand the Fixed Roads command group.

-

To define a new road, click New and enter a unique Name. Alternatively, pick an existing road from the list.

Tip: You can also pick a road interactively in the Pit Design 3D window.

-

By default, the road is enabled as Use is checked. You can uncheck this box to remove the road from the design (and re-enable it later if needed).

-

Define a Gradient for the road in degrees, as a ratio or as a percentage, and will be a primary maximum constraint (it will not be exceeded for operational reasons).

-

Set the Width of the fixed road. The width is applied across the entire fixed road.

-

Choose Start Point and click in the 3D view (right-click to snap to existing data) once to define the start of the road, and again to denote the end position and elevation.

-

Use the Edit Centerline commands to fine-tune the centerline of the fixed road. You can also do this after road calculation or before.

Delete: remove the currently active fixed road centreline string from the collection.

Move Centreline: enables the move-strings2d command. The active fixed road centreline can be repositioned within its current elevation and/or rotated using the modifier controls. It is possible to move a fixed road so that either the start, end or both points cannot be integrated into the design. In this situation, the Output window will highlight the situation.

Insert Curve: the insert-curve command is really useful for modifying a fixed road string, particularly if a smooth curve is required.

Move Points: enables point editing mode to allow you to modify the active fixed road string vertices. This command responds to both left-click (on-section) or right-click (snapping) modes. It is often useful to snap a start or end point to a known crest or toe string, for example. Cancel the command when you're finished. More about move-points-mode...

Insert Line: modify your fixed road centreline string by inserting a new line segment. This can be used to either increase or decrease the complexity of the string. More about insert-line...

Insert / Delete Points: runs the insert-points-mode and delete-points-mode commands respectively. You will need to Cancel these commands when you're finished.

Note: The commands shown are shortcuts to other design commands found elsewhere in the system. You can use any string editing command to alter the centerline.

-

Once your centerline is as you want it, click Recalculate.

-

Regenerate your pit or dump surface and review.

-

Save your project.

Configure Outputs and Visual Settings

Various tools appear at the bottom of the panel. They are used to recalculate design data and set visual formatting options, and can be applied in any order:

-

Show Dump Constraints: Adding constraint strings is a simple case of selecting 1 or more Phase Shell Contours (for pit designs) or dump profile perimeters (for dump designs), then clicking Add selected string(s).

-

Show Fixed Road Centrelines: This option is only available if at least one fixed road has been added to the scenario. If so, the status of this setting determines if all fixed roads are displayed or hidden.

Whilst you can't hide and show individual fixed roads, you can enable or disable fixed roads independently via the Fixed Roads command group.

-

Object Generation Options

These options relate to which optional data is created when scenario results (design strings or phase surface) are generated. By default, these options are unchecked.

-

Mark Design Strings Below Topo

Select this option to format the dump design string(s) below the assigned topography. This can be a useful indicator of roughly where the dump intersects with the topography.

To access this setting, a topography must be specified for the current pit.

Note: Generated design string data contains an INSIDE attribute, set to 1 or 0 depending on whether the string data that is generated is within the pit or outside it. This attribute can be used for filtering, for example.

-

Create Surface Intersect Strings with Wireframe Generation

If enabled, will automatically generate a string that aligns to the intersection of the specified topography surface(s) and generated design surface. This is applied when the Make Design Surface button is clicked. This will show precisely where the topography passes through dump surface data. If there is no intersection, no string is created.

Note: these additional design string data representing intersections will have a "CONTACT" value for the TYPE attribute.

-

Combine Design Surface With Topo

A useful option if you wish to generate a design surface that is merged with the assigned topography.

To access this setting, a topography must be specified for the current pit.

If selected, the Make Design Surface command automatically intersects the generated pit or dump surface with the nominated topography, essentially trimming the dump phase shell to remove surface data that falls below the topography.

-

-

Show Design Strings and Recalculate: design strings can be hidden or displayed using this check box. This control is only available if design strings have been created at least once within the current project session.

Clicking Recalculaterecreates a series of strings representing the pit or dump geometry. This is where the regional parameters (face angles, berm widths), road definition, and constraint strings are interrogated to ensure they are honored during pit string generation.

All defined lifts are used to project the pit design upwards or downwards, although if a topography is specified, additional visualization options become available (see above) and will be applied when design strings are recalculated.

-

Show Design Surface and Make Design Surface: Once a suitable set of design strings can be seen in the Task window, click Make Design Surface to create a DTM that will represent the dump shell comprising all defined lifts, roads etc. Once generated, you can show or hide the surface. Make Design Surfacealways utilizes the latest design strings to generate a dump surface.

The generated shell is accessible by the Reserves processes (Add DTMs, Create Phase Solids etc.) when the Auto Design task is saved.

This command is also available on the Auto Design toolbar.

Note: If Auto Evaluation is selected (see below) evaluation results are output the Design Evaluation control bar, updating any existing values in line with any changes in the automatically-created design surface. Selecting this command clears existing evaluation results from the Design Evaluation control bar (see below).

-

Show Design Solids: enable this check box to display the enclosed volumes for the selected design. This check box is only available if an automated design has been previously created.

-

Show Topography: Only accessible if a topography is associated with the selected Pit. Toggles the display of the specified topography surface file.

-

Show Slope Region Strings—if slope region boundaries have been specified using the Define Slopes task, you can toggle their display here. If no slope region boundaries exist for your project, this option is unavailable.

-

Create Overlays: Typically, auto desisn data is automatically unloaded when the task is closed. However, you can create persistent and reusable 3D window objects and overlays from any generated design data if you want. Selecting Create Overlays displays the 3D Objects screen, from which you can select any loaded data object to convert into an object and overlay that will persist when the design task is closed. This could be useful for reporting or additional volume calculations (such as cut and fill) for example.

Evaluation settings

These options become available once design strings exist. , and a topography has been assigned to the pit or dump.

Note: If no topography is specified for the current pit, evaluations are based on volumes created by closing the uppermost design string.

Pit volumes can be reported by category and/or per bench and dump volumes by lift:

-

Auto Evaluation: if checked, evaluation results (representing the volume that results from an intersection of the generated design surface and topography assigned to the selected Pit) are output to the Design Evaluation control bar each time you recreate the design surface.

-

Report by Bench: if unchecked, summary evaluation results (per evaluation category) will be displayed when the Evaluate button is pressed (or a surface created and Auto Evaluation enabled). If checked, the output report will include per bench and per category results.

For example, the image below shows output with the Report by Bench option enabled (red boundary) and with it unchecked (blue boundary):

You can also use Evaluate to manually trigger an evaluation of the current design surface/topography intersecting. This button and the Auto Evaluation option is inaccessible if no design surface exists yet.

Where pit volume is detected outside of the model,

it will be reported in its own table row, e.g.:

This command is also available on the Auto Design toolbar.

Related topics and activities